Product Description

Welcome visit us. Contact us today and we will deliver an accurate casting quote within 2 working days!

Why Choose Us?

1. We have 15 years experience in crusher spare parts with low price and high quality.

2. All kinds of surface treatments are available: Polishing, Epoxy Coatings, zinc plating, nickel plating, powder coating, e-coating, DIP coating, phosphate coating, anodizing, painting, etc…

3. We can provide castings, fabrications, deep drawing, machining, welding and assembly.

4. Roviding samples with important dimensions and customizing inspection report, material certification to customer for validation and verification

5. We specialize in fast turn around with low volume orders. Please CHINAMFG your specification for quoting.

Details–

Jaw stock is the main spare parts of Jaw crusher. Swing Jaws lay on it.

material of jaw stock: carbon steel or according to customer requirement

surface treatment: shot blast& oil& painting

MOQ: 1pc

Production time: 6weeks for first piece and pattern, following 4pcs within 4weeks

Technology: sand casting& machining

Casting workshop

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| After-sales Service: | One Year |

|---|---|

| Warranty: | One Year |

| Certification: | CE, RoHS, ISO 9001:2000 |

| Standard: | AISI, ASME, BS, ANSI, JIS, GB, GOST, ASTM, DIN |

| Surface Treatment: | Sand Blast |

| Manufacturing Process: | Casting |

| Samples: |

US$ 6000/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Can planetary gears be used in automotive applications?

Planetary gears are widely used in various automotive applications due to their numerous advantages. Let’s explore how planetary gears can be utilized in the automotive industry:

- Automatic Transmissions:

One of the primary applications of planetary gears in automobiles is in automatic transmissions. Automatic transmissions use a combination of planetary gear sets to achieve different gear ratios, allowing for smooth and efficient shifting between gears. The compact size and high torque capacity of planetary gears make them well-suited for this purpose, providing reliable and efficient power transmission in vehicles.

- Four-Wheel Drive Systems:

Planetary gears are also employed in four-wheel drive systems, where they help distribute power between the front and rear wheels. By utilizing planetary gear arrangements, the torque can be split between the front and rear axles, providing improved traction and stability on various road conditions. This allows vehicles to have enhanced off-road capabilities and better performance in challenging driving situations.

- Hybrid and Electric Vehicles:

Planetary gears play a crucial role in hybrid and electric vehicle powertrains. In these vehicles, planetary gear sets are often used to combine the power from the internal combustion engine and the electric motor. The gear arrangement allows for seamless transitions between different power sources, enabling efficient energy management and optimized performance.

- Start-Stop Systems:

Start-stop systems, which automatically shut off the engine when the vehicle is stationary and restart it when needed, often incorporate planetary gears. These gears help engage and disengage the engine from the drivetrain smoothly, ensuring a quick and seamless transition between the engine’s off and on states. Planetary gears contribute to the overall efficiency and reliability of start-stop systems.

- Power Steering:

Some power steering systems in automobiles utilize planetary gears to provide assistance in steering. These gears help amplify the driver’s input torque, making steering easier and more responsive. The compact size and high torque capacity of planetary gears make them suitable for power steering applications.

In summary, planetary gears find extensive use in automotive applications, including automatic transmissions, four-wheel drive systems, hybrid and electric vehicle powertrains, start-stop systems, and power steering. Their compact size, high torque capacity, and ability to achieve multiple gear ratios make them well-suited for these applications, providing efficient power transmission, improved performance, and enhanced driving experience in vehicles.

How do planetary gears contribute to speed reduction and torque amplification?

Planetary gears offer the capability of both speed reduction and torque amplification, making them versatile components in various mechanical systems. Let’s explore how planetary gears achieve these functions:

- Speed Reduction:

Planetary gears can reduce rotational speed by utilizing their gear arrangement. The key elements involved in speed reduction are the sun gear, planet gears, and ring gear. Consider the following scenarios:

- Epicyclic Gear Set:

In a basic planetary gear arrangement, when the sun gear is used as the input and the ring gear is fixed, the planet gears rotate on their own axes while also revolving around the sun gear. This configuration causes the output speed to be lower than the input speed. The reduction in speed is determined by the gear ratios between the sun gear, planet gears, and ring gear.

- Multiple Stages:

Planetary gears can be combined into multiple stages, with each stage having its own set of sun gears, planet gears, and ring gears. By connecting the output of one stage to the input of another, the rotational speed can be further reduced. This allows for greater flexibility in achieving the desired speed reduction in complex mechanical systems.

- Torque Amplification:

Planetary gears are also capable of amplifying torque, enabling them to handle higher loads and provide increased output torque. The torque amplification occurs in the following scenarios:

- Epicyclic Gear Set:

When the sun gear is used as the input and the ring gear is the output, the planet gears rotate on their own axes while also revolving around the sun gear. This arrangement allows for torque amplification, meaning the output torque can be higher than the input torque. The specific torque amplification factor depends on the gear ratios and the number of planet gears in the system.

- Combination of Gear Stages:

By combining multiple stages of planetary gears, torque amplification can be further increased. Each stage contributes to the overall torque amplification, allowing the system to handle even higher loads and transmit greater torque.

In summary, planetary gears contribute to speed reduction by utilizing the gear ratios between the sun gear, planet gears, and ring gear. They achieve torque amplification by utilizing the arrangement of the gears in an epicyclic gear set, as well as through the combination of multiple gear stages. These capabilities make planetary gears valuable in various applications where speed reduction and torque amplification are required, such as automotive transmissions, industrial machinery, and power transmission systems.

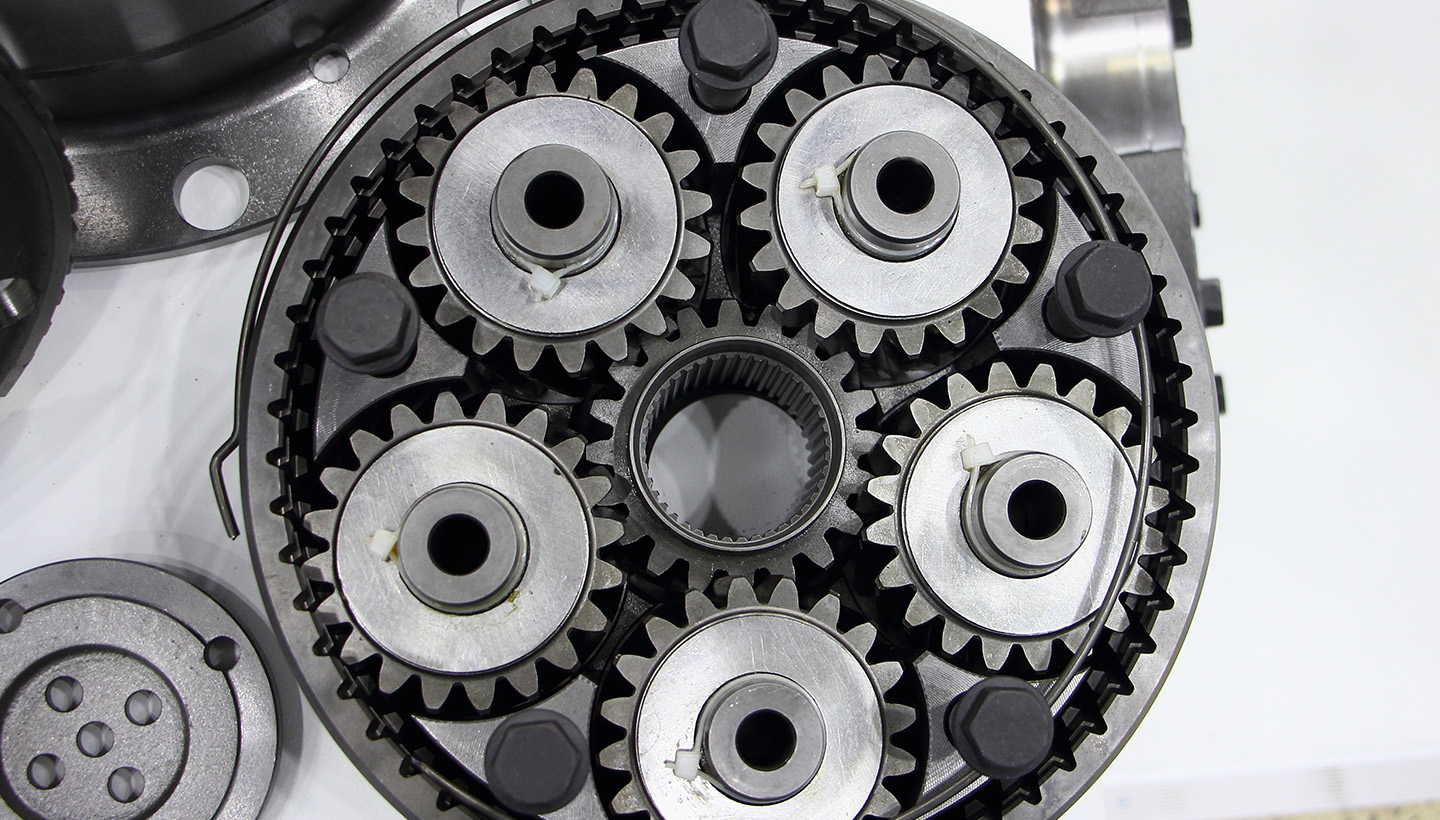

Can you explain the unique design and structure of planetary gears?

Planetary gears possess a unique design and structure that sets them apart from other gear systems. Let’s explore the distinctive features of the design and structure of planetary gears:

- Components:

A planetary gear system consists of three main components: the sun gear, planet gears, and a ring gear. The sun gear is located at the center and is typically driven by an input source such as a motor or engine. The planet gears are gears that surround the sun gear and are connected to a carrier or arm. The ring gear is the outermost gear and meshes with the planet gears.

- Internal Gear Meshing:

One of the distinguishing features of planetary gears is their internal gear meshing. Unlike other gear systems where the gears mesh externally, the teeth of the sun gear, planet gears, and ring gear are located on the inside surfaces. This arrangement allows for a compact and space-efficient design.

- Orbiting Motion:

In planetary gears, the planet gears exhibit both rotational and orbital motion. While they rotate on their own axes, they also orbit around the sun gear. This combination of rotational and orbital movement enables the gear system to achieve different gear ratios and torque transmission.

- Central Sun Gear:

The presence of a central sun gear is another characteristic of planetary gears. The sun gear is positioned at the center of the gear arrangement and serves as the primary driver for the overall gear operation. It receives the input power and transmits it to the planet gears.

- Versatile Gear Ratios:

Planetary gears are capable of achieving a wide range of gear ratios. The gear ratio is determined by the relative sizes of the gears and the number of teeth on each gear. By varying the number of teeth on the sun gear, planet gears, and ring gear, different gear ratios can be obtained, providing versatility in speed reduction or amplification.

- Load Distribution:

The arrangement of multiple planet gears in a planetary gear system helps distribute the load among the gears. This load distribution results in efficient torque transmission and enhanced durability. It also contributes to shock absorption and noise reduction during gear operation.

- Compact Size:

Planetary gears are known for their compact size. The internal gear meshing and the integration of multiple gear sets within a single system contribute to their space-saving design. The compactness of planetary gears is advantageous in applications where size and weight restrictions are critical.

- Wide Range of Applications:

Due to their unique design and structural characteristics, planetary gears find applications in various industries and mechanical systems. They are commonly used in automotive transmissions, robotics, aerospace systems, industrial machinery, and more. The ability to achieve different gear ratios, transmit torque efficiently, and operate in compact spaces makes planetary gears versatile in transmitting power.

In summary, the unique design and structure of planetary gears include components such as the sun gear, planet gears, and ring gear, internal gear meshing, orbiting motion of the planet gears, a central sun gear, versatile gear ratios, load distribution, compact size, and wide-ranging applications. These features contribute to the efficiency, versatility, and space-saving nature of planetary gears, making them suitable for various mechanical systems.

editor by Dream 2024-04-30